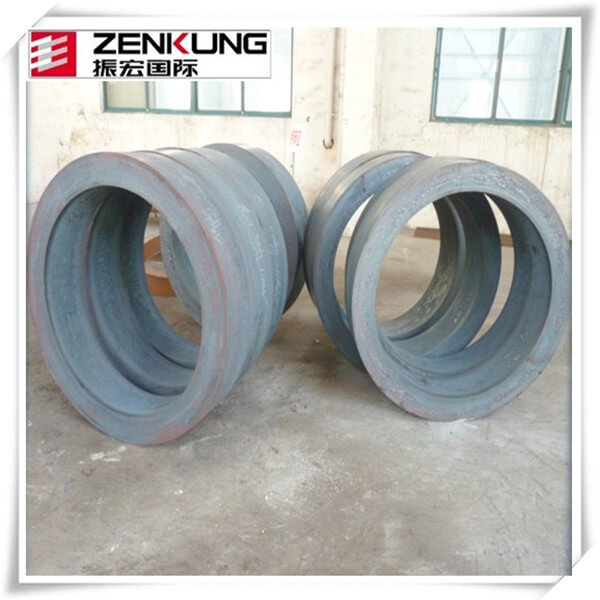

Name: 4140 forged ring rolling flange backing ring shaft collar

Material: 16Mn;50Mn;42CrMo;15MnV;35CrMo;A105;20#;SUS304;304L;316L;410SS and so on

Main production process: forging + heat treatment + rough machining

Standards: ASTM, ASME, DIN, JIS, ISO, BS, API, EN

Testing items

Chemical analysis, Tensile test ( yield strength, tensile strength, breaking elongation ), Impact resistance test, Hardness Testing, UT, Surface crack detection, Dimensional inspection

Production capacity

1.Open die forging:

Max OD: 3800mm; Max weight: 35t; Max height: 2500mm.

2.Ring rolling:

OD: 600mm~3800mm; Min ID: 500mm; Max weight: 4t; Max height: 500mm.

|

OD:

|

|

|

Min ID:

|

|

|

Max Weight:

|

|

|

Max Height:

|

|

| Name | 4140 forged ring rolling flange backing ring shaft collar of China |

| Material | 16Mn;50Mn;42CrMo;15MnV;35CrMo;A105;20#;SUS304;304L;316L;410SS and so on |

| Main production process | forging + heat treatment + rough machining |

| Standards | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Testing items | Chemical analysis, Tensile test ( yield strength, tensile strength, breaking elongation ), Impact resistance test, Hardness Testing, UT, Surface crack detection, Dimensional inspection |

| Production capacity | 1.Open die forging: Max OD: 3800mm; Max weight: 35t; Max height: 2500mm. 2.Ring rolling: OD: 600mm~3800mm; Min ID: 500mm; Max weight: 4t; Max height: 500mm. |

42CrMo steel forging flange backing ring rolling 42CrMo steel forging flange backing ring rolling

Raw Material:

Carbon steel, C-Mn steel, alloy structure steel, alloyed tool steel, cold roll steel, steel for pressure vessel, carburizing steel, die steel, stainless steel and so on.

| Wind Turbine Shaft | 42CrMo,42CrMo4,34CrNiMo6 |

| Marine Shaft | C-Mn Steel |

| Hydro Turbine Shaft | 20SiMn and so on |

| Roller Shaft | 70Cr3Mo;9Cr2Mo;MC1;MC2;MC3;AISI4130;AISI4330;AISI4150;AISI4350;AISI4340;410SS and so on |

| Gear shaft | 17CrNiMo6;18CrNiMo7-6;20CrNi2Mo;42CrMo;47CrNiMo6;20CrMnMo and so on |

| Gear | 17CrNiMo6;18CrNiMo7-6;20CrNi2Mo;42CrMo;47CrNiMo6;20CrMnMo;30CrNiMo8 and so on |

| Pressure Vessel Forgings | SA105;SA350 LF2;16Mn; S355J2; 20MnMo; 15MnMo; 12Cr2Mo;14CrMo;42CrMo;42CrMo4;AISI4130;AISI4330;SA266;SA182;SUS304;SA336 |

| Ring Rolling | 16Mn;50Mn;42CrMo;15MnV;35CrMo;A105;20#;SUS304;304L;316L;410SS and so on |

* As we manufacture customized products, other materials are also appreciated.

For blank, with iron frame.

For semi-finish and finish products, painted with antirust oil, packed with plastic film and packaged into a wooden case.

Package is upon your request!

alloy steel forged rotor used ring rolling machine

Superiorities

1. High precision of dimensional tolerance.

2. Excellent mechanical properties.

3. Available in varieties of dimensions (acc to customer's requirements).

4. Advanced production equipments and test instruments.

5. 42 excellent technicians.

6. The production procedures are strictly controlled.

7. Much attention is also paid to the protection and packaging.

1- About Us

We are the leading manufacturer of heavy forging steel parts, our business is custom fabrication forging by customer's drawings and technical requirement. We are the member of “ Confederation of Chinese Metalforming Industry”.

2- Main Product: Shaft, Step Shaft, Gear & Gear Shaft, Flange, Pipe Fitting, Bearing, and others.

alloy steel forged rotor used ring rolling machine

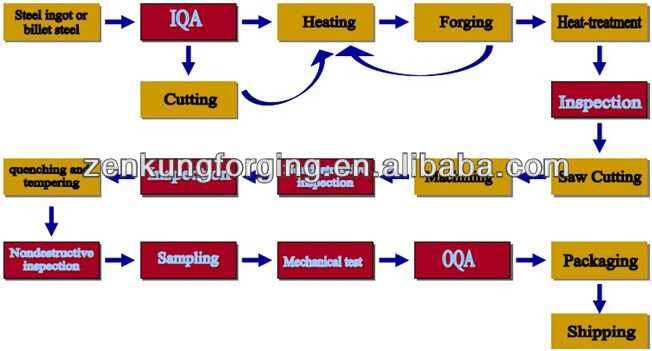

Production Flow Chart

alloy steel forged rotor ring rolling pipe fitting

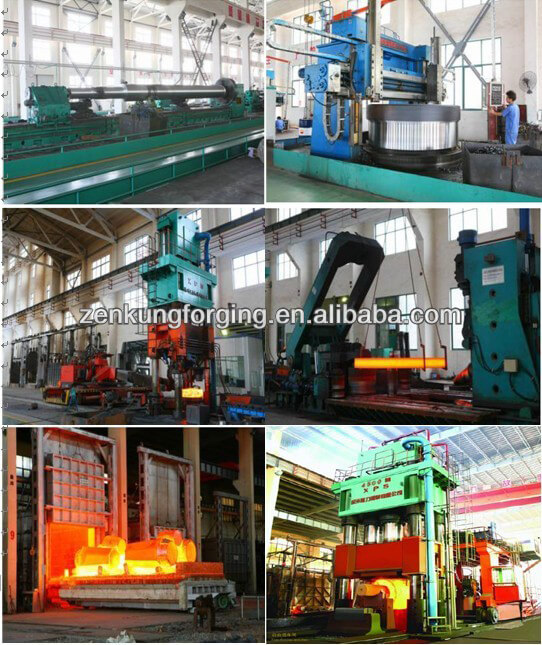

Main Equipments

alloy steel forged rotor used ring rolling machine

Testing Instruments

alloy steel forged rotor used ring rolling machine

Certificates

ISO 9001:2008, PED Certificate, TUVRheinland, Bureau Veritas (BV), Lloyd Register (LR), ABS, RINA, Germanischer Lloyd (GL), Korean Register of Shipping (KR), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK).

alloy steel forged rotor used ring rolling machine

Company Environment

Main Clients Overseas

GE, ABB, BOSCH, PMG, FFF, QSC.

About the price

The price includes quenching and tempering cost.

Specific price is determined by the material and your specific requirements.